PVC Stabilizer Failures & Troubleshooting

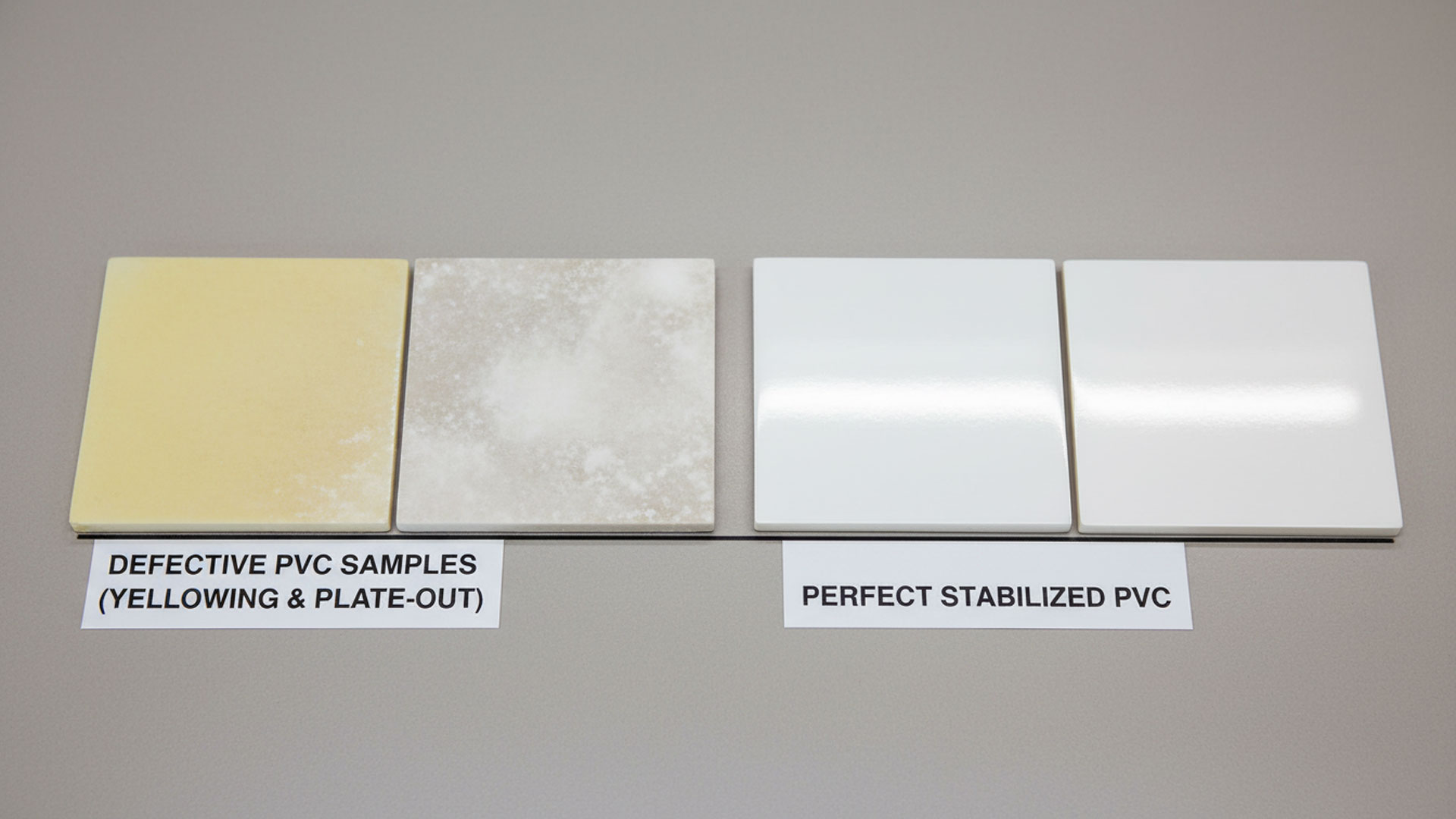

Stabilizers play a vital role in PVC processing. Incorrect stabilizer selection or dosage can lead to yellowing, plate-out, odor formation, degradation and poor mechanical properties.

1. Common Stabilization Problems

1) Yellowing / Color Deviation

Causes:

Low stabilizer dosage

Incorrect Ca-Zn ratio

Excessive heat exposure

Improper lubricant system

Fix:

Optimize Ca-Zn stabilizer

Reduce processing temperature

Adjust lubricant package

2) Plate-Out Formation

Causes:

Poor heat stability

High volatility additives

Lubricant incompatibility

Fix:

Use high-stability Ca-Zn systems

Switch to lower-volatility plasticizers

Modify lubricant ratios

3) Odor / Gas Emission

Causes:

Plasticizer incompatibility

Insufficient stabilization

Low purity raw materials

Fix:

Choose DOTP/TOTM

VOC-optimized stabilizers

Cleaner PVC resin

Conclusion

Most stabilization problems can be solved through proper stabilizer selection, plasticizer compatibility and optimized processing conditions.