How Plasticizers Affect Mechanical Properties

Plasticizers directly influence PVC’s flexibility, strength, elongation, low-temperature performance and processability. Selecting the right plasticizer is essential for final product performance.

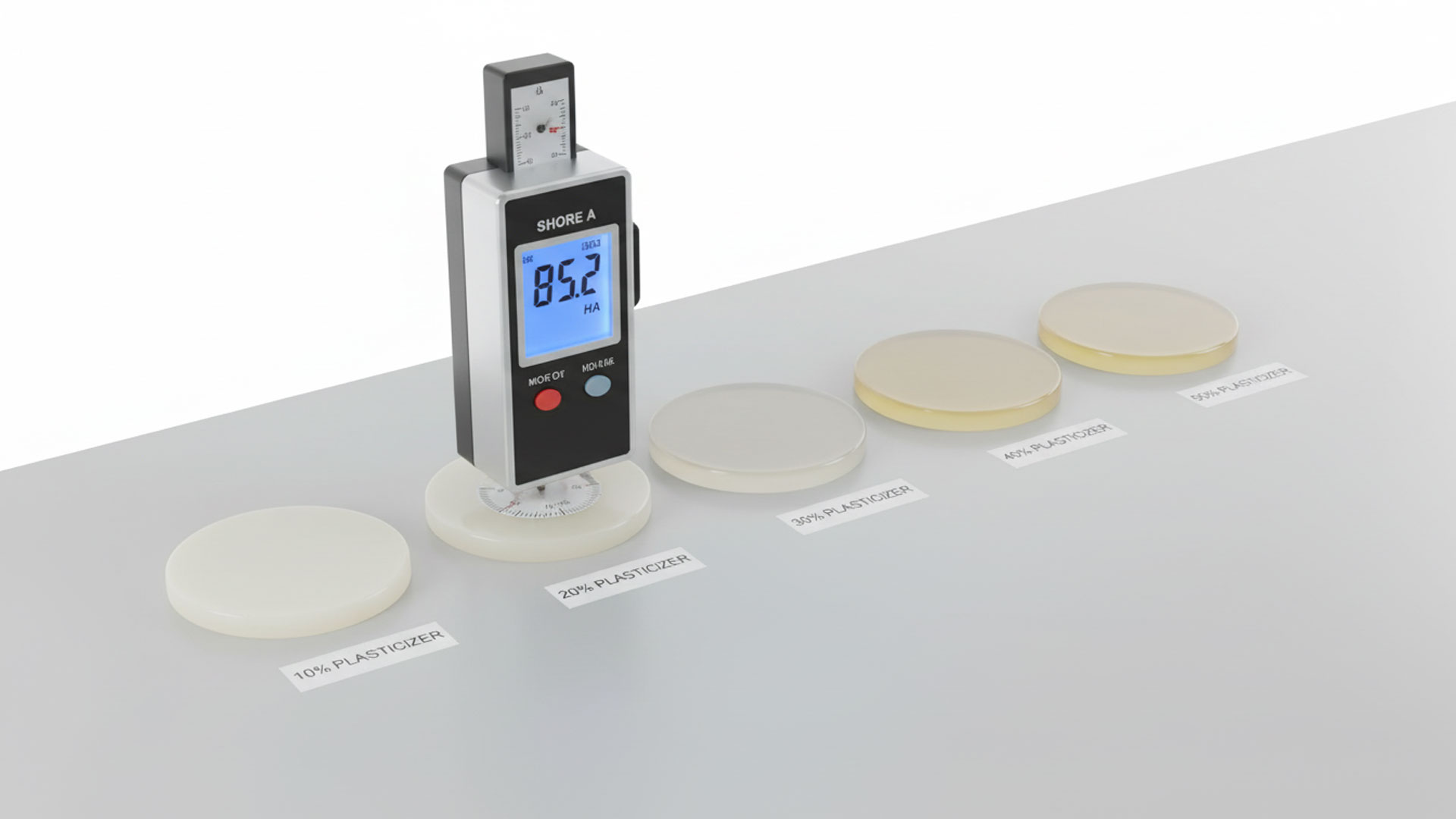

1. Flexibility & Hardness

Higher plasticizer content → lower Shore hardness and increased flexibility.

• DOP, DINP → general-purpose

• DOTP → stable flexibility

• DOA → excellent cold-temperature performance

2. Tensile Strength & Elongation

Aromatic vs. linear ester structure changes polymer mobility:

• Aromatic esters → stronger mechanical properties

• Linear esters → softer yet balanced performance

3. Low-Temperature Behavior

Critical for hoses, outdoor cables, food-grade films.

DOA and TOTM maintain flexibility below –20°C.

4. Processability

Plasticizer choice affects:

✓ fusion time

✓ torque

✓ viscosity

✓ extrusion speed

Conclusion

The mechanical behavior of PVC is fundamentally shaped by the plasticizer system chosen for the formulation.